Honda HR-V: Reassembly - CVT Transmission Disassembly and Reassembly (CVT)

NOTE:

- Refer to the Exploded View as needed during this procedure.

- Keep all foreign particles out of the transmission.

- When you reassemble the transmission, apply a light coat of clean transmission fluid on all oil seals, O-rings, and bearings. Also soak the forward clutch assembly and the reverse brake discs, in clean transmission fluid for at least 30 minutes prior to installation.

1. Reverse Brake Piston - Install

.png)

- Install the reverse brake piston (A) with new O-rings (B)

- Install the spring retainer/return spring (C).

.png)

- Put the reverse brake spring compressor attachment on the spring

retainer/return

spring assembly (A).

NOTE: Be sure the attachment is set over the return springs, not on the reverse brake piston (B)

- Install the reverse brake spring compressor plate (C) with facing the UP mark to the upside using bolts (D)

- Make sure that the reverse brake spring compressor bolt (E) is properly installed on the dent in the surface of the reverse brake spring compressor attachment (F)

- Compress the return springs using the reverse brake spring compressor until the snap ring securing the spring retainer/return spring can be installed

- Install a new snap ring (G).

NOTE:

- Be careful not to deform the snap ring by opening/closing it excessively.

- Make sure the snap ring is firmly installed in the groove.

- Remove the reverse brake spring compressor.

2. Reverse Brake Disc and Plate - Install

.png)

- Install the disc spring (A).

NOTE: Be sure to install the disc spring with the indented mark (B) facing the upward.

- Starting with the reverse brake plate (C), alternately install the reverse brake plates and the reverse brake discs (D).

- Install the reverse brake end-plate (E) with the flat side toward the top disc.

- Install a new snap ring (F).

NOTE:

- Be careful not to deform the snap ring by opening/closing it excessively.

- Make sure the snap ring is firmly installed in the groove.

3. Reverse Brake End-Plate Thrust Clearance - Inspect

- Set a dial indicator (A) on the reverse brake end-plate (B).

.png)

- Zero the dial indicator with the reverse brake end-plate is lifted up to the snap ring (C)

- Release the reverse brake end-plate

- Put the clutch compressor attachment and the clutch compressor attachment 64 mm on the reverse brake end-plate

- Press the clutch compressor attachment down with 39 N (4.0 kgf, 8.8 lbf) (the weight of the clutch compressor attachment is included) using a force gauge, and read the dial indicator

- The dial indicator reads the clearance (D) between the reverse brake end-plate and the top disc (E). Take measurements in at least three places, and use the average as the actual clearance.

Standard: 1.0-1.2 mm (0.039-0.047 in)

- If the clearance is out of the standard, remove the reverse brake end-plate and select a suitable one.

- 3.6 mm (0.142 in)

- 3.7 mm (0.146 in)

- 3.8 mm (0.150 in)

- 3.9 mm (0.154 in)

- 4.0 mm (0.157 in)

- 4.1 mm (0.161 in)

- 4.2 mm (0.165 in)

- 4.3 mm (0.169 in)

- 4.4 mm (0.173 in)

- 4.5 mm (0.177 in)

- 4.6 mm (0.181 in)

- 4.7 mm (0.185 in)

- 4.8 mm (0.189 in)

- 4.9 mm (0.193 in)

- 5.0 mm (0.197 in)

- Install a selected reverse brake end-plate, then recheck the clearance.

4. Sun Gear, Planetary Carrier, and Ring Gear - Install

.png)

- Install the ring gear (A), the thrust washer (B), and the collar (C) as shown

- Install the planetary carrier (D) and the thrust needle bearing (E) as shown

- Install the 33 x 40 mm thrust shim (F) and the sun gear (G)

- Install a new snap ring (H) using the snap ring pliers.

NOTE:

- Be careful not to deform the snap ring by opening/closing it excessively.

- Make sure the snap ring is firmly installed in the groove.

5. Sun Gear Thrust Clearance - Inspect

- Set a dial indicator (A) on the sun gear (B).

.png)

- Zero the dial indicator with the sun gear is lifted up to the 33 x 40 mm thrust shim (C) contact the snap ring (D)

- Release the sun gear

- Put the clutch compressor attachment on the sun gear

- Press the clutch compressor attachment down with 49 N (5.0 kgf, 11.0 lbf) (the weight of the clutch compressor attachment is included) using a force gauge, and read the dial indicator

- The dial indicator reads the clearance (E) between the sun gear and the 33 x 40 mm thrust shim. Take measurements in at least three places, and use the average as the actual clearance.

Standard: 0.04-0.09 mm (0.0016-0.0035 in)

- If the clearance is out of the standard, remove the 33 x 40 mm thrust shim and select a suitable one.

- 1.31 mm (0.0516 in)

- 1.34 mm (0.0528 in)

- 1.37 mm (0.0539 in)

- 1.40 mm (0.0551 in)

- 1.43 mm (0.0563 in)

- 1.46 mm (0.0575 in)

- 1.49 mm (0.0587 in)

- 1.52 mm (0.0598 in)

- 1.55 mm (0.0610 in)

- 1.58 mm (0.0622 in)

- 1.61 mm (0.0634 in)

- 1.64 mm (0.0646 in)

- 1.67 mm (0.0658 in)

- 1.70 mm (0.0669 in)

- 1.73 mm (0.0681 in)

- 1.76 mm (0.0693 in)

- 1.79 mm (0.0705 in)

- 1.82 mm (0.0717 in)

- 1.85 mm (0.0728 in)

- Install a selected 33 x 40 mm thrust shim, then recheck the clearance.

6. Stator Shaft and Input Shaft - Install

- Install new sealing rings (A).

.png)

- Check the needle bearing (B). If the needle bearing is worn or damaged, replace it

- Install the input shaft (C) by aligning the clutch discs (D) with the splines (E)

- Install a new sealing ring (F)

- Install the stator shaft (G) with the 26 x 38.8 mm thrust shim (H) and the thrust needle bearing (I) as shown.

7. Transmission Fluid Lubrication Pipe and Baffle Plate - Install

.png)

Fig. 40: Baffle Plate With Torque Specifications

- Install the transmission fluid lubrication pipe (A) by aligning the guide tab (B) with the guide hole (C)

- Install the baffle plate (D).

8. Oil Pump Drive Sprocket Sealing Ring - Install

.png)

- Install a new sealing ring (A).

9. Manual Valve Body and Stator Shaft Flange - Install

.png)

Fig. 41: Manual Valve Body and Stator Shaft Flange With Torque Specifications

- Install the stator shaft flange (A) with the dowel pins (B) (C) by aligning the transmission fluid lubrication pipe (D) and the dowel pins (B) with the mounting holes (E)

- Install the manual valve body (F) with the separator plate (G) and the dowel pins (H).

10. Control Shaft - Install

.png)

Fig. 42: Control Shaft With Torque Specifications

- Install the detent lever (A) by aligning the guide tab (B) with the groove (C).

- Install the control shaft (D)

- Install the roller (E) by aligning the mounting hole (F) with the groove (G)

- Secure the control shaft with a new lock washer (H), then pry up the lock tab (I) of the lock washer against the bolt head

- Install the detent spring (J).

11. Transmission Fluid Pump Drive Sprocket and Transmission Fluid Pump Drive Chain - Install

.png)

- Install the transmission fluid pump drive sprocket (A) and the transmission fluid pump drive chain (B)

- While expanding a new snap ring (C) of the transmission fluid pump drive

sprocket

using the snap ring pliers, install the transmission fluid pump drive

sprocket.

NOTE:

- Be careful not to deform the snap ring by opening/closing it excessively.

- Make sure the snap ring is firmly installed in the groove.

12. Final Drive Shaft and Differential Assembly - Install

.png)

- Install the final drive shaft assembly (A) and the differential assembly (B).

13. Torque Converter Housing - Install

.png)

- Remove all of the old liquid gasket from the mating surfaces of the transmission housing and the torque converter housing, the bolts, and the bolt holes

- Clean and dry the mating surfaces of the transmission housing and the torque converter housing

- Apply liquid gasket (Honda Genuine Liquid Gasket 5460H) to the

transmission

housing surface and to the inside edge of the threaded bolt holes. Install

the

component within 4 minutes of applying the liquid gasket.

NOTE:

- Apply a 1.5 mm (0.059 in) diameter bead of liquid gasket along the broken line (A) which is 3.9 mm (0.154 in) from the chamfering surface of the transmission housing inner side.

- Do not apply any liquid gasket to the bolt hole.

- Apply the liquid gasket all around as shown. When the bead is arriving at the end point, overlap the liquid gasket.

- The torque converter housing must be installed within 4 minutes. If too much time has passed after applying the liquid gasket, remove the old liquid gasket and residue, then reapply new liquid gasket.

- Do not touch the applied liquid gasket face.

.png)

Fig. 43: Torque Converter Housing With Torque Specifications (2WD)

.png)

Fig. 44: Torque Converter Housing With Torque Specifications (AWD)

- Install the torque converter housing (A) with the dowel pins (B), and

tighten the

bolts in a crisscross pattern in at least two steps.

NOTE:

- Wait for at least 1 hour before filling the transmission with transmission fluid.

- Do not run the engine for at least 3 hours after installing the torque converter housing.

14. Parking Brake Pawl - Install

.png)

Fig. 45: Parking Brake Pawl With Torque Specifications

- Install the parking brake rod holder (A) and a new lock washer (B)

- Pry up the lock tab (C) of the lock washer against the bolt head

- Install the parking brake pawl (D) with the parking shaft (E) and the parking pawl spring (F).

15. Transmission Fluid Pipe and Transmission Fluid Cooler Pipe - Install

.png)

Fig. 46: Transmission Fluid Pipe and Transmission Fluid Cooler Pipe With

Torque Specifications

- Install the transmission fluid pipes (A) with new O-rings (B)

- Install the transmission fluid cooler pipe (C).

16. End Cover - Install

.png)

- Install new sealing rings (A).

.png)

- Remove all of the old liquid gasket from the mating surfaces of the transmission housing and the end cover, the bolts, and the bolt holes

- Clean and dry the mating surfaces of the transmission housing and the end cover

- Apply liquid gasket (Honda Genuine Liquid Gasket 5460H) to the

transmission

housing surface and to the inside edge of the threaded bolt holes. Install

the

component within 4 minutes of applying the liquid gasket.

NOTE:

- Apply a 1.5 mm (0.059 in) diameter bead of liquid gasket along the broken line (A) which is 3.9 mm (0.154 in) from the chamfering surface of the end cover inner side.

- If too much time has passed after applying the liquid gasket, remove the old liquid gasket and residue, then reapply new liquid gasket.

- The end cover must be installed within 4 minutes. If too much time has passed after applying the liquid gasket, remove the old liquid gasket and residue, then reapply new liquid gasket.

- Do not touch the applied liquid gasket face.

.png)

Fig. 47: End Cover With Torque Specifications

- Install the end cover (A) with the dowel pins (B), and tighten the bolts

in a

crisscross pattern in at least two steps.

NOTE:

- Wait for at least 1 hour before filling the transmission with transmission fluid.

- Do not run the engine for at least 3 hours after installing the end cover.

17. Transmission Fluid Pump - Install

.png)

Fig. 48: Transmission Fluid Pump With Torque Specifications

- Install the transmission fluid pump (A) with the dowel pins (B).

18. Solenoid Wire Harness - Install

.png)

Fig. 49: Solenoid Wire Harness With Torque Specifications

- Connect the connectors (A).

- Install the transmission fluid temperature sensor (B)

- Install the ground terminals (C) and the harness clamps (D).

19. Valve Body Assembly - Install

.png)

- Install the transmission fluid pipes (A) with new O-rings (B).

- Install the solenoid wire harness subconnector (A) with a new O-ring (B).

.png)

Fig. 50: Valve Body Assembly With Torque Specifications

- Connect the connector (C)

- Install the valve body (D).

NOTE: Do not damage the solenoid wire harness (E) while installing the valve body assembly.

Length of Bolt

F - 90 mm (3.54 in)

G - 65 mm (2.56 in)

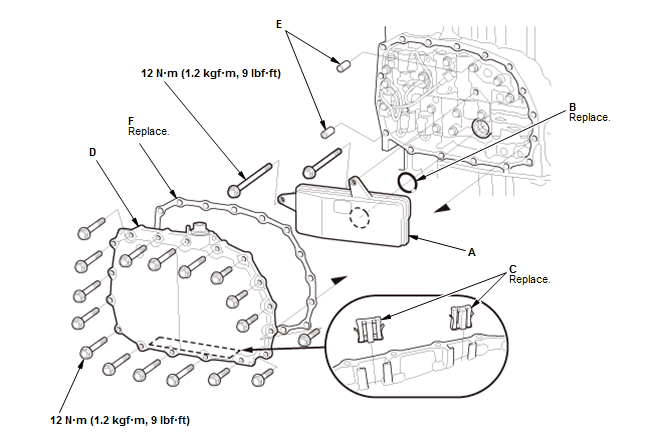

20. Transmission Fluid Pan and Transmission Fluid Strainer - Install

Fig. 51: Transmission Fluid Pan and Transmission Fluid Strainer With Torque

Specifications

- Install the transmission fluid strainer (A) with a new O-ring (B).

NOTE: Do not damage the solenoid wire harness while installing the transmission fluid strainer.

- Install new magnets (C)

- Install the transmission fluid pan (D) with the dowel pins (E) and a new

gasket (F), and tighten the bolts in a crisscross pattern in at least two

steps.

NOTE: Do not damage the solenoid wire harness while installing the transmission fluid pan.

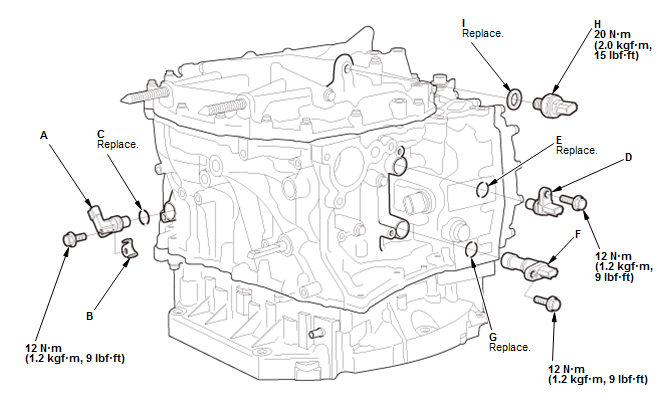

21. Sensor - Install

Fig. 52: Sensor With Torque Specifications

- Install the CVT speed sensor (A) with the sensor washer (B) and a new O-ring (C).

- Install the CVT drive pulley speed sensor (D) with a new O-ring (E)

- Install the torque converter turbine speed sensor (F) with a new O-ring (G)

- Install the CVT driven pulley pressure sensor (H) with a new sealing

washer (I).

NOTE: Be careful not to damage the plastic part.

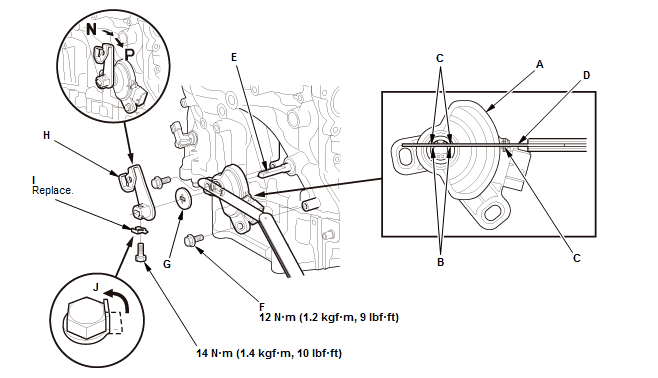

22. Transmission Range Switch - Install

Fig. 53: Transmission Range Switch With Torque Specifications

- Set the transmission range switch (A) to the N position. Align the

cutouts (B) on the rotary-frame with the N positioning cutouts (C) on the

transmission range switch, then put a 2.0 mm

(0.079 in) feeler gauge (D) in the cutouts to hold the transmission range

switch in the N position.

NOTE: Be sure to use a 2.0 mm (0.079 in) feeler gauge or equivalent to hold the transmission range switch in the N position.

- Install the transmission range switch gently on the control shaft (E) while holding it in the N position with the 2.0 mm (0.079 in) feeler gauge

- Tighten the bolts (F) on the transmission range switch while you continue holding the N position

- Remove the feeler gauge

- Install the control shaft cover (G)

- Install the control lever (H) with a new lock washer (I)

- Pry up the lock tab (J) of the lock washer against the bolt head

- Turn the control lever to the P position.

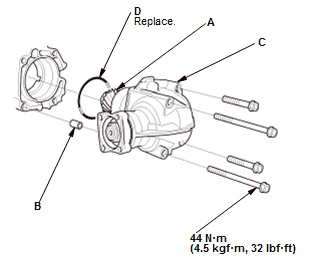

23. Transfer Assembly - Install (With AWD)

Fig. 54: Transfer Assembly With Torque Specifications

- Apply a light coat of clean transmission fluid to the transfer mount and transfer driven gear (A)

- Install the dowel pin (B)

- Install the transfer (C) with a new O-ring (D).