Honda HR-V: Starter System Circuit Troubleshooting (Without Keyless Access System)

NOTE:

- Air temperature must be between 59-100ºF (15-38ºC) during this procedure.

- After the inspection, you must reset the PCM. Otherwise, the PCM will continue to stop the fuel injectors from operating.

- The 12 volt battery must be in good condition and fully charged.

1. Starting system check 1.

- Connect the HDS to the DLC.

- Turn the vehicle to the ON mode.

- Select ALL INJECTORS STOP in the PGM-FI INSPECTION menu with the HDS.

ALL INJECTORS STOP

- With the transmission in neutral (M/T), P or N (CVT), and with the clutch pedal (M/T) or the brake pedal (CVT) pressed, turn the vehicle to the START mode to crank the engine.

Did the starter crank the engine?

YES

Do the PCM reset in the PGM-FI system to cancel ALL INJECTORS STOP with the HDS.

NO

Go to step 2.

2. Starting system check 2.

- Turn the vehicle to the OFF (LOCK) mode.

- Check the 12 volt battery condition. Check the electrical connections at

the 12 volt battery, the 12 volt

battery negative cable to the body, the engine ground cables, and the

starter for looseness and corrosion.

Then try starting the engine again.

Did the starter crank the engine?

Starter cranks normally

Repairing the loose connection corrected the problem. Do the PCM reset in the PGM-FI system to cancel ALL INJECTORS STOP with the HDS.

Starter does not crank engine at all

If the starter does not crank the engine at all, go to step 3.

Starter cranks abnormally

If the starter cranks the engine erratically or too slowly, go to step 5.

Starter overruns

If the starter does not disengage from the flywheel ring gear (M/T) or the torque converter ring gear (CVT) when you release the key, replace the starter, or remove and disassemble it, and check for the following:

- Dirty drive gear or damaged overrunning clutch

- Damaged flywheel ring gear (M/T) or torque converter ring gear (CVT)

3. Fuse check.

- Check the following fuse.

Are the fuse OK?

YES

Reinstall the fuse, then go to step 4.

NO

Replace the fuse, and recheck. If the fuse blows again, repair the short to ground on the No. C16 (7.5 A) fuse circuit.

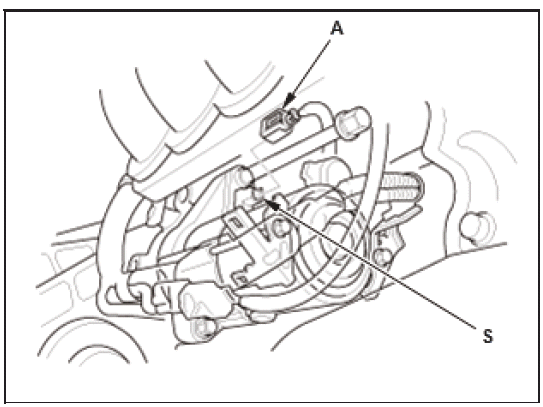

4. Determine possible failure area (starter, starter circuit).

- Make sure the transmission is in neutral (M/T), P or N (CVT).

- Disconnect the following connector.

Starter S terminal 1P connector (A)

- Connect terminals A and B with a jumper wire.

Did the starter crank the engine?

YES

Check the following items in the order listed until you find the problem in the circuit:

- Check for an open or short in the wire and connectors between the ignition switch and the starter cut relay.

- Check for an open or short in the wire and connectors between the starter cut relay and the starter.

- Check for an open in the wire and connectors between the starter cut relay and clutch pedal position switch A. (M/T)

- Check for poor connections or loose terminals at clutch pedal position switch A and ground G302. (M/T)

- Check for an open in the wire and connectors between the starter cut relay and the transmission range switch. (CVT)

- Check for poor connections or loose terminals at the transmission range switch and ground G101. (CVT)

- Check for faulty ignition switch.

- Check for faulty starter cut relay.

- Check for faulty clutch pedal position switch A. (M/T)

- Check for faulty transmission range switch. (CVT)

NO

Check for an open or short in the wire and connectors between the 12 volt battery and the starter.

Replace the starter, or remove and disassemble it, as necessary.

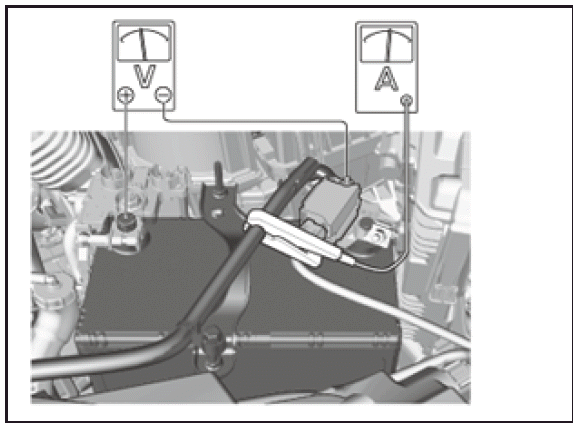

5. Starter test.

- Connect the following equipment:

- Ammeter, 0-400 A

- Voltmeter, 0-20 V (accurate within 0.1 V)

- Do the STARTING TEST, check the cranking voltage and the current draw from the following service limit table.

.png)

Are the cranking voltage and the current draw within the service limits?

YES

Remove the starter, and inspect its drive gear and the flywheel ring gear (M/T) or the torque converter ring gear (CVT) for damage. Replace any damaged parts.

NO

Replace the starter or remove and disassemble it, and check for these problems:

- Drag in the starter armature

- Shorted armature winding

- Excessive drag in the engine

- Open circuit in the starter armature commutator segments

- Excessively worn starter brushes

- Open circuit in the starter brushes

- Dirty or damaged helical splines or drive gear

- Faulty overrunning clutch

WIRING DIAGRAM

STARTING SYSTEM ELECTRONIC WIRING DIAGRAM

Refer to appropriate wiring diagram. System Wiring Diagrams

COMPONENT LOCATION INDEX

STARTING SYSTEM COMPONENT LOCATION INDEX

.png)